Job shadowing to Finland from 12 to 13 August 2024

The programme and job shadowing were organised by host organisation Freudenberg Home & Cleaning Solutions Oy – Aiki Hoffmann and Petteri Enne.

The participants went job shadowing in Vileda’s factory in Finland, where they went through the different stages of production from start to finish – material selection, sewing, eco-friendliness and environmental sustainability. Participants were taught how to use Vileda tools correctly to achieve maximum results with the right ergonomic techniques.

Fascinating facts about Vileda production

- Only 0–1 kg of non-recyclable waste is generated in one day at the Vileda factory.

- Around 1,300,000 Swep mops are produced each year.

- 22% of the total electricity consumption of the Vileda factory comes from solar energy.

- Vileda is testing a robot that would produce mops. At the moment, an experienced worker can do the same job better and faster than a sewing robot.

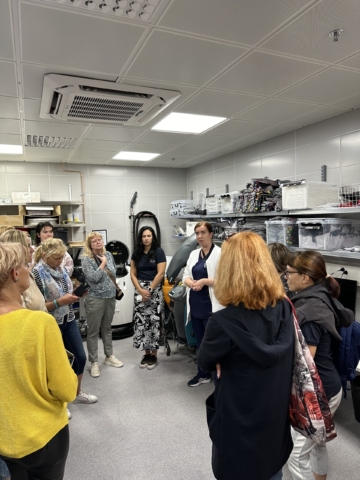

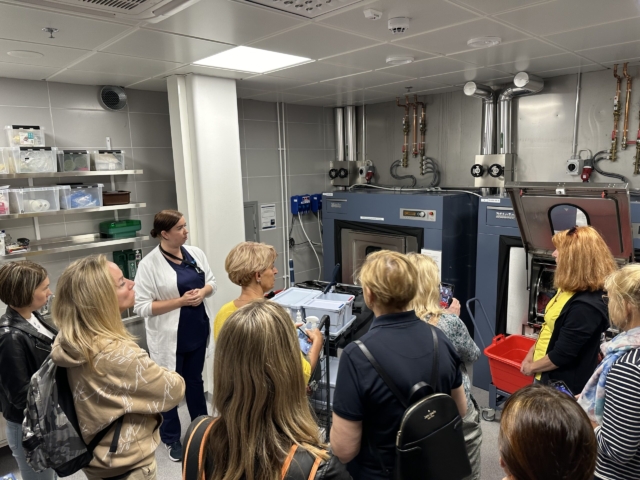

The group also went job shadowing at Helsinki University Central Hospital (HUS). We were welcomed by the service manager of the hospital, which is just two years old. During job shadowing, participants learned how the work of the cleaning staff is divided in the hospital and what tools and methods they mainly use, taking into account criteria governing eco-friendliness. They identified the best practices for organising cleaning tasks in the hospital environment from the point of view of HUS. It turned out that a large number of the tools are from the Vileda range. The bed washing machine, mattress washing machine, mop pre-washing machine and trolley washing machine were seen as the most innovative tools.

To sum up:

- HUS has separate rooms for cleaning items (crutches, wheelchairs, beds, trolleys) and there are designated employees for this.

- There are large integrated machines for cleaning and disinfecting beds and trolleys. Since they fit fully in the machines, the result is 100% clean.

- There is a separate clean room for making up the beds with everything you need.

- There are separate refuse bins and even chutes for sorting rubbish.

- Measuring cups, urine bottles, bedpans and other such containers are also cleaned in a dedicated room. This room and all the previously mentioned rooms have a clean side and a non-clean side.

The article was compiled by: Tiina Matsi, Tertu Hendrikson